Engineering

Made in Germany from A to Z

Our team of highly qualified engineers forms the basis for innovative and sustainable solutions. Our motto is: Where others give up, our engineers are dedicated to solving unusual customer problems.

Plant & Process Optimisation

extrutec offers a comprehensive consulting and modernisation service to ensure that your systems provide the best imaginable productivity and corresponding function within the product life cycle. Our employees have many years of experience. They work together with you to develop bespoke solutions that amortise quickly. We reliably implement changes to your production lines.

Service Range:

- Modernisation of automation systems, replacement of entire control systems, implementation of remote maintenance systems

- Mechanical heater conversions, burner modifications, etc.

- Adaptation of inductors with regard to geometry, power, and energy consumption

- Modifications of power electronics, power supply systems

- Retrofitting of safety equipment

- Extensions of facilities (saws, preheating equipment, material handling)

Conversions & Retrofitting

Our team is working constantly to develop detailed solutions and further optimisation of existing plant components and processes in order to warrant above-average plant availability while making maintenance easier. Apart from improvements of the smallest details, this includes retrofitting of larger and more complex components. Small changes are often all it takes for great progress towards simplifying maintenance, increasing process reliability, and improving plant availability.

We offer you the following retrofitting options for conversion/retrofitting in the scope of optimising your existing facility:

Gas heater systems

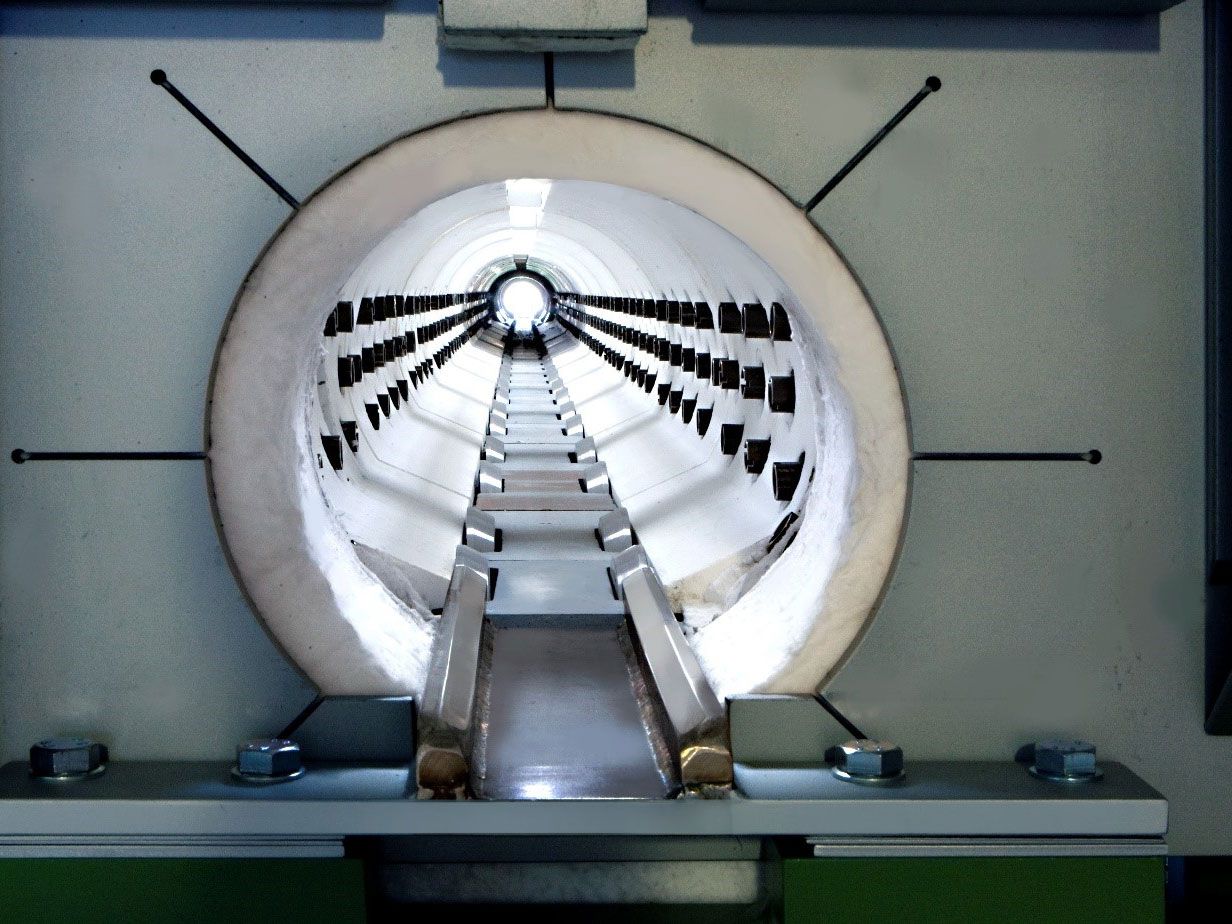

Induction heater systems

Technical Documentation

Extrutec understands technical documentation as an important part of a machine. Our modern documentation system ensures up-to-date content, both in print and digital formats. Our focus is primarily on detailed maintenance information that is easy to find via tables of contents and keyword indexes. Many illustrations and a clear layout elevate our operating manuals above the average.

- Output printed in folder, as PDF or HTML application

- In future also as personalized cloud solution as single point of truth

- High-quality, individual operating instructions

- spare parts lists, supplier documentation, safety data sheets and drawings

Special Solutions

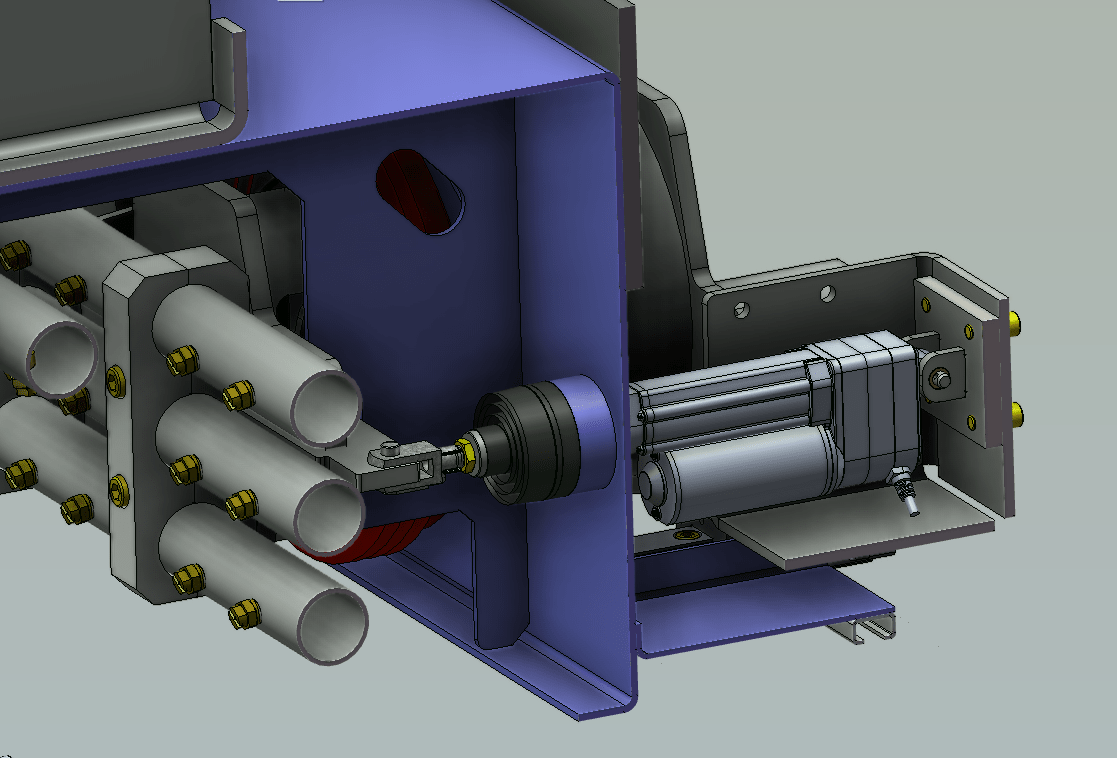

Water quenching with nozzle holders that can be applied by electric motor is one example of a special solution.

This concept allows flexible adjustment of the distance between nozzle and profile, minimising water consumption or reducing energy consumption.

Consulting

How may we help you?

We offer advice in all matters regarding heating, cooling, and material handling, and help you find technical solutions for your ideas. Our experience and know-how in the field of heating technology for forming processes, heat treatment concepts in aluminium extrusion plants, and a wide range of special solutions allow us to point out available options and to advise you on choosing the best concept for your specific requirements.

We also help you in planning, support you with new acquisitions, analyse the potential of your existing plants or processes or show you existing improvement possibilities.

News

Fairs