Aftersales

Our experienced aftersales team...

...ensures that your issues are addressed quickly, reliably and competently. We offer a wide range of service and maintenance services and spare parts for extrutec as well as third-party systems.

Depending on the customers requirements we perform the service either worlwide on site or in our modern production facility in Menden. Together with our subsidiary TCT Induktionstechnik GmbH, we operate a state-of-the-art production facility in Menden. The vertical integration this facility provides allows for the optimum control of the quality of our products and services.

You can reach our

aftersales department:

+49 7732 939-1341 or by email:

aftersales@extrutec-gmbh.de

Spare parts

Aftersales extrutec is your competent partner for all spare parts. We offer a full range of high-quality spare parts for all extrutec systems. Our many years of experience and our commitment to quality make us the first choice for your spare parts. Rely on our expertise and our first-class service and minimize downtimes. Our competent team is always available to answer your questions.

Spare parts controls equipment

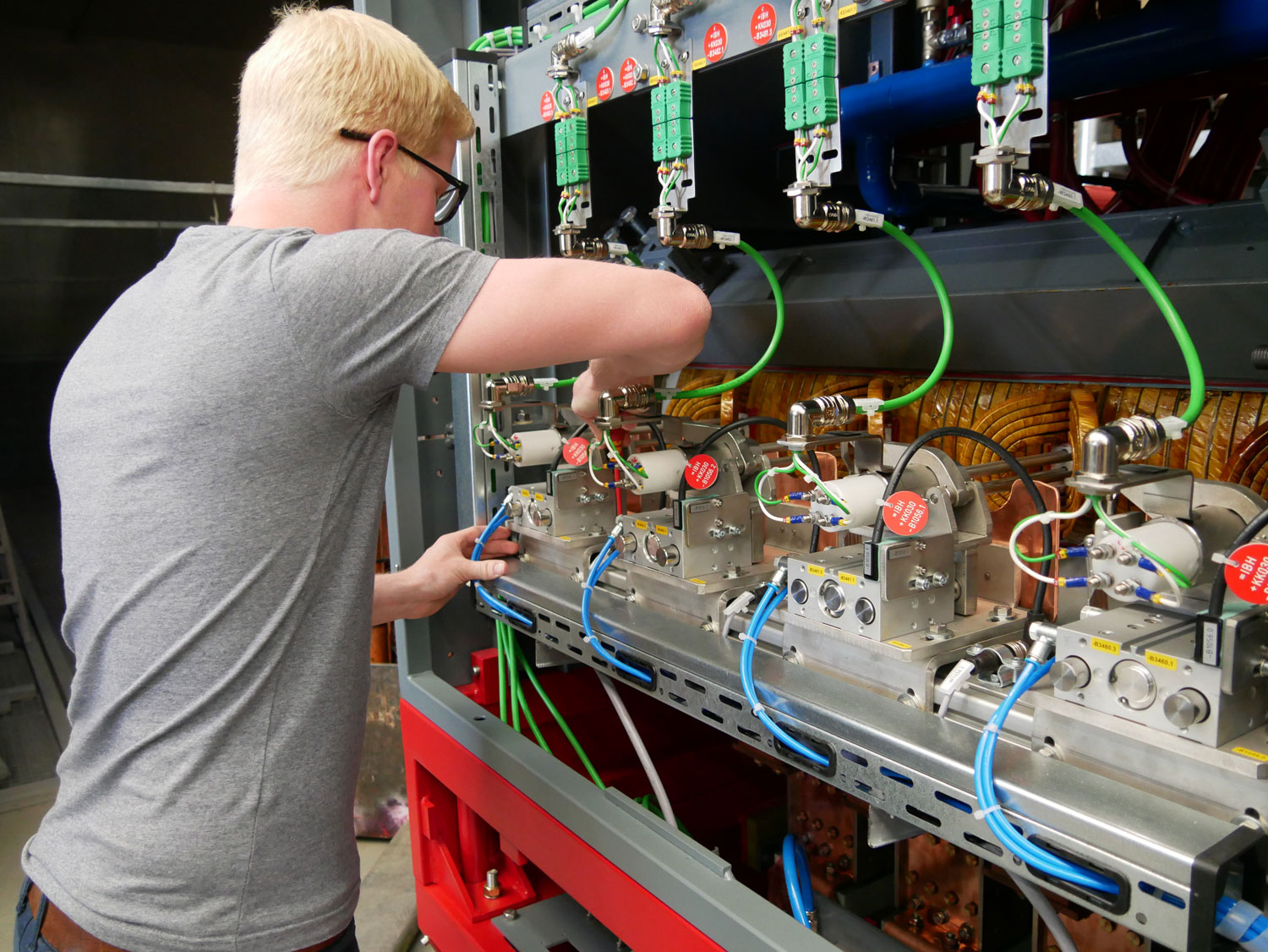

IGBT converter

water cooled cables

IGBT driver boards

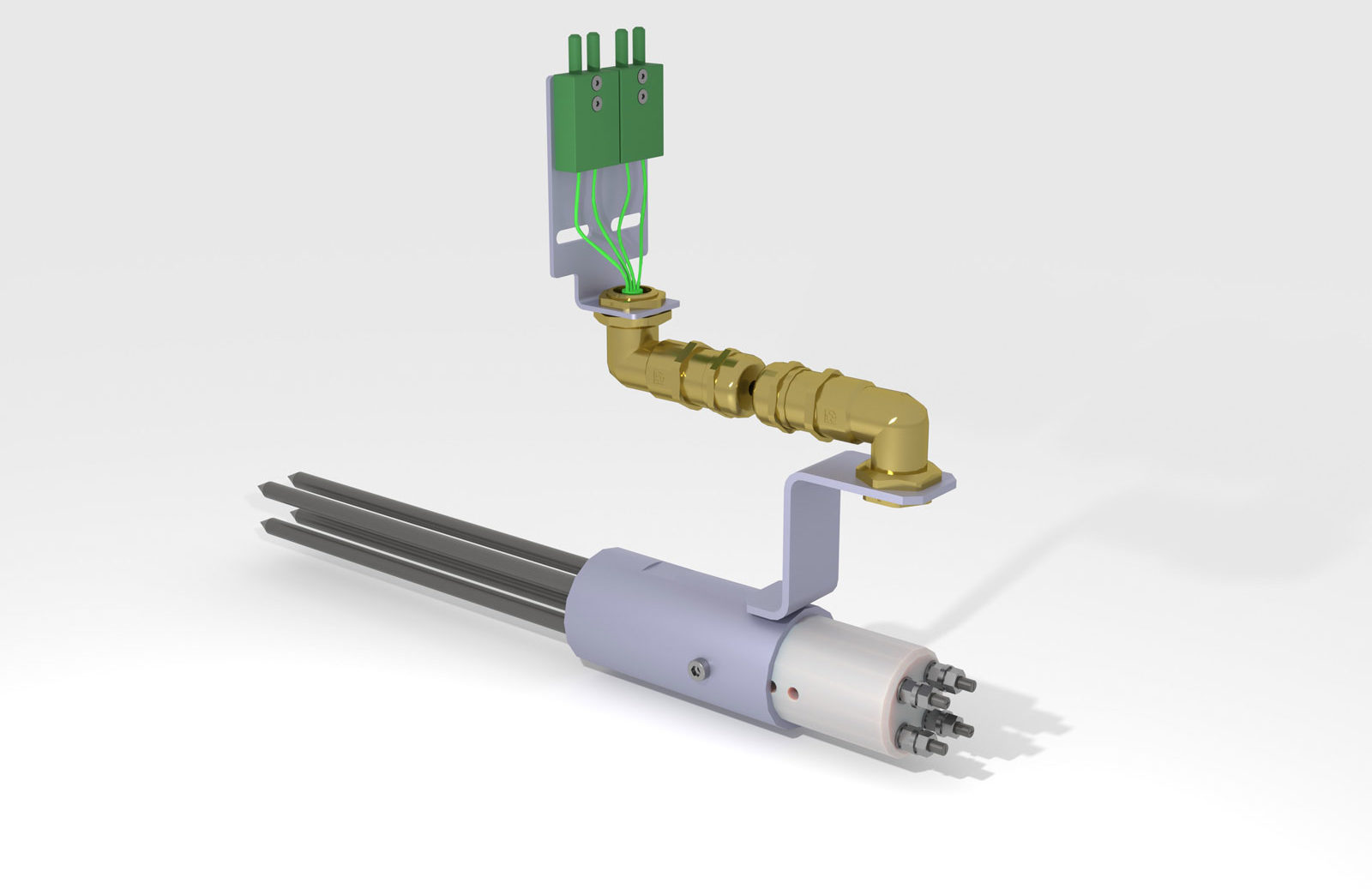

thermocouple cables sliding

plates/charging tray

(induction furnace)

Spare parts heating equipment

ceramic hearth shells

burner nozzles

thermocouple unit

gas-air mixer valve

Accessories

Extrulube

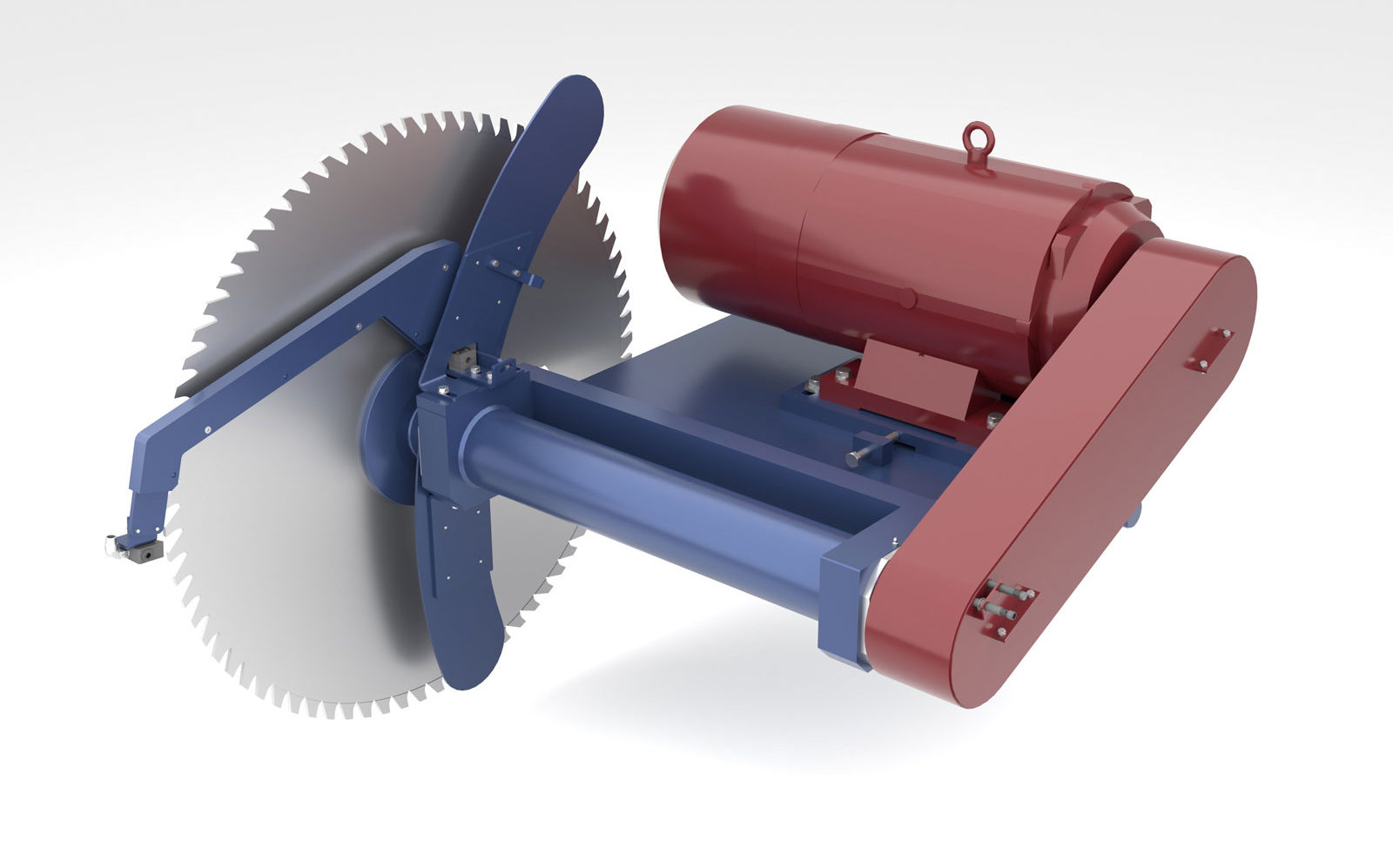

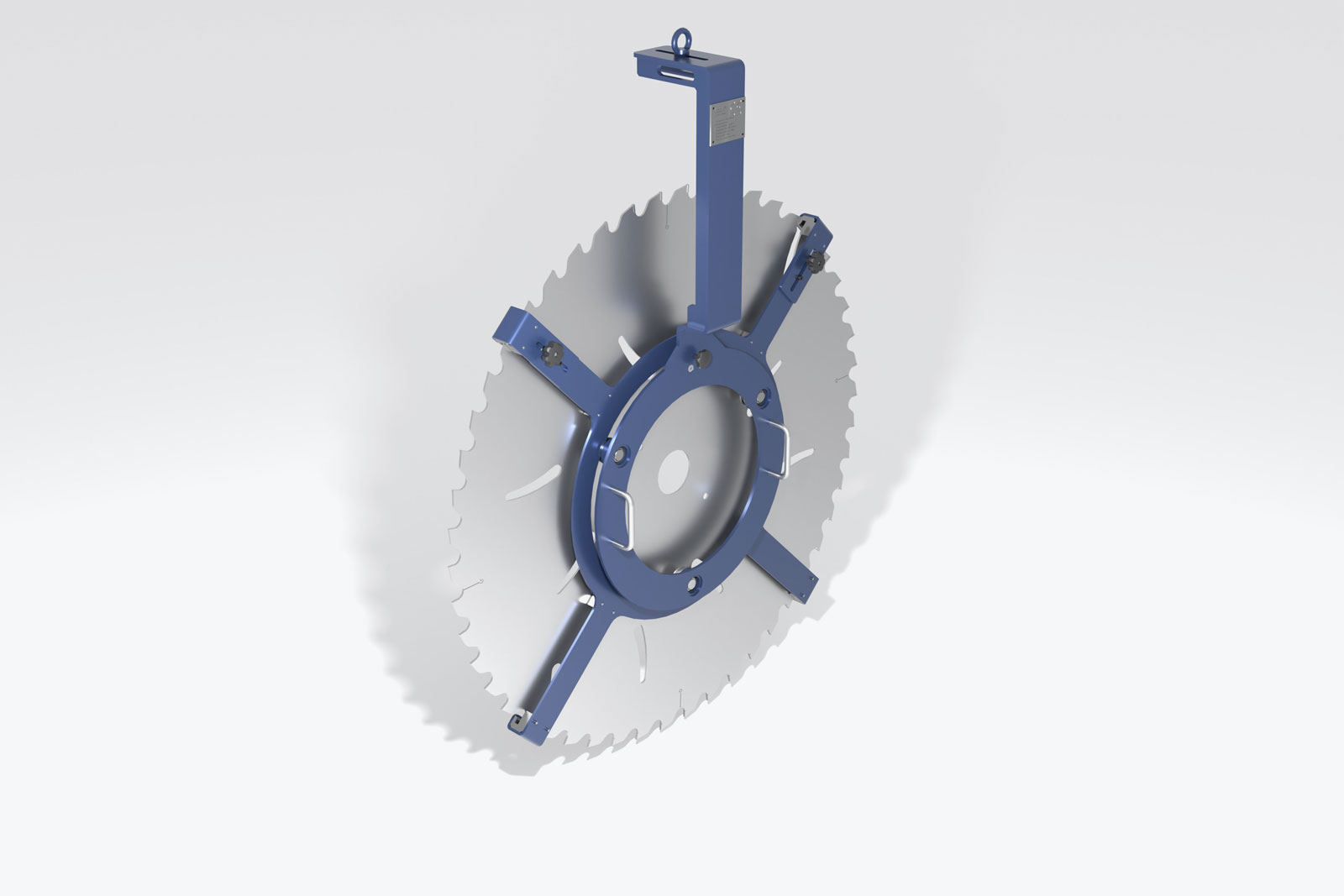

saw blade lubrication

kevlar furnace seals

jig for saw blade changes

remote support modem

saw blades

Online spare parts catalog

You can view all spare parts and the relevant information in our online spare parts catalog. You can also make an inquiry or place an order there or alternatively send it to us using the contact form below.

Request spare parts by mail: aftersales@extrutec-gmbh.de

or by email: aftersales@extrutec-gmbh.de

Repair & Maintenance

We service your plants, repair them if damaged or suffering total failure, modernise or retrofit them, and support you at short notice if you are experiencing a plant shutdown. We offer professional advice for any work.

Service Range for Gas Heater Systems

- Online support and troubleshooting in case of unexpected system downtime

- Remote maintenance with camera support

- On-site stocktaking and error analysis

- Development of detailed optimisation proposals

- Gas technical inspection and adjustment of the heating

- Reduction of consumption

- Minimisation of emissions

- Emission measurements and documentation

- Repair of complete gas heater systems

Service Range for Induction Heater Systems

- Repair of complete induction plants and induction coils

- Mounting and commissioning

- Performance optimisations and modernisations

- New production and delivery of individual components

- EMC measurements

- Inverter service

Service partner TCT Induktionstechnik

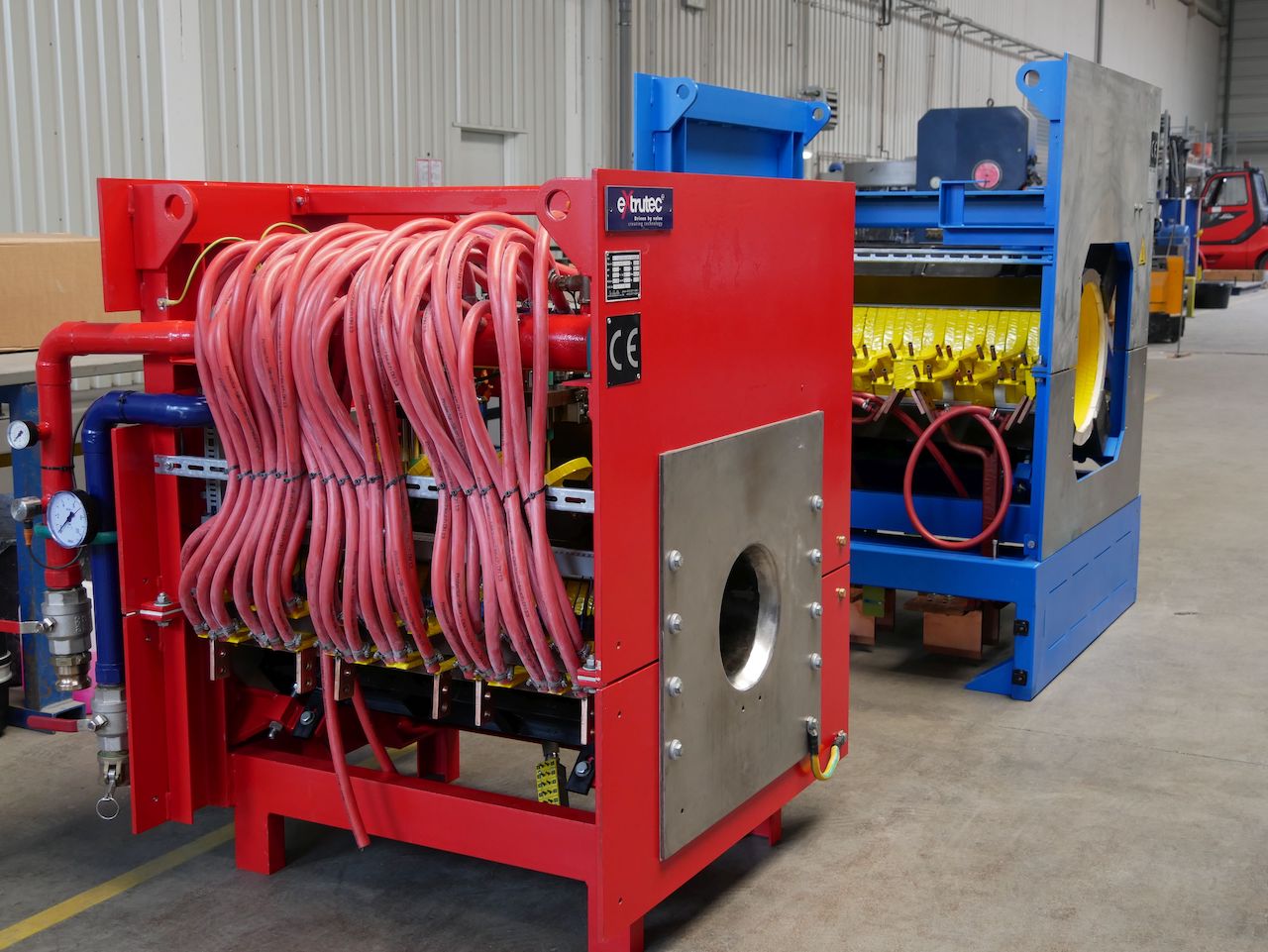

With the acquisition of its subsidiary TCT Induktionstechnik GmbH at the turn of 2020/21, extrutec has also significantly expanded its own service offering. With its own production facilities and expanded storage options, it is possible to act much faster and in a higher flexible way.

The product portfolio, which can be offered in close cooperation with TCT Induktionstechnik, includes the following services:

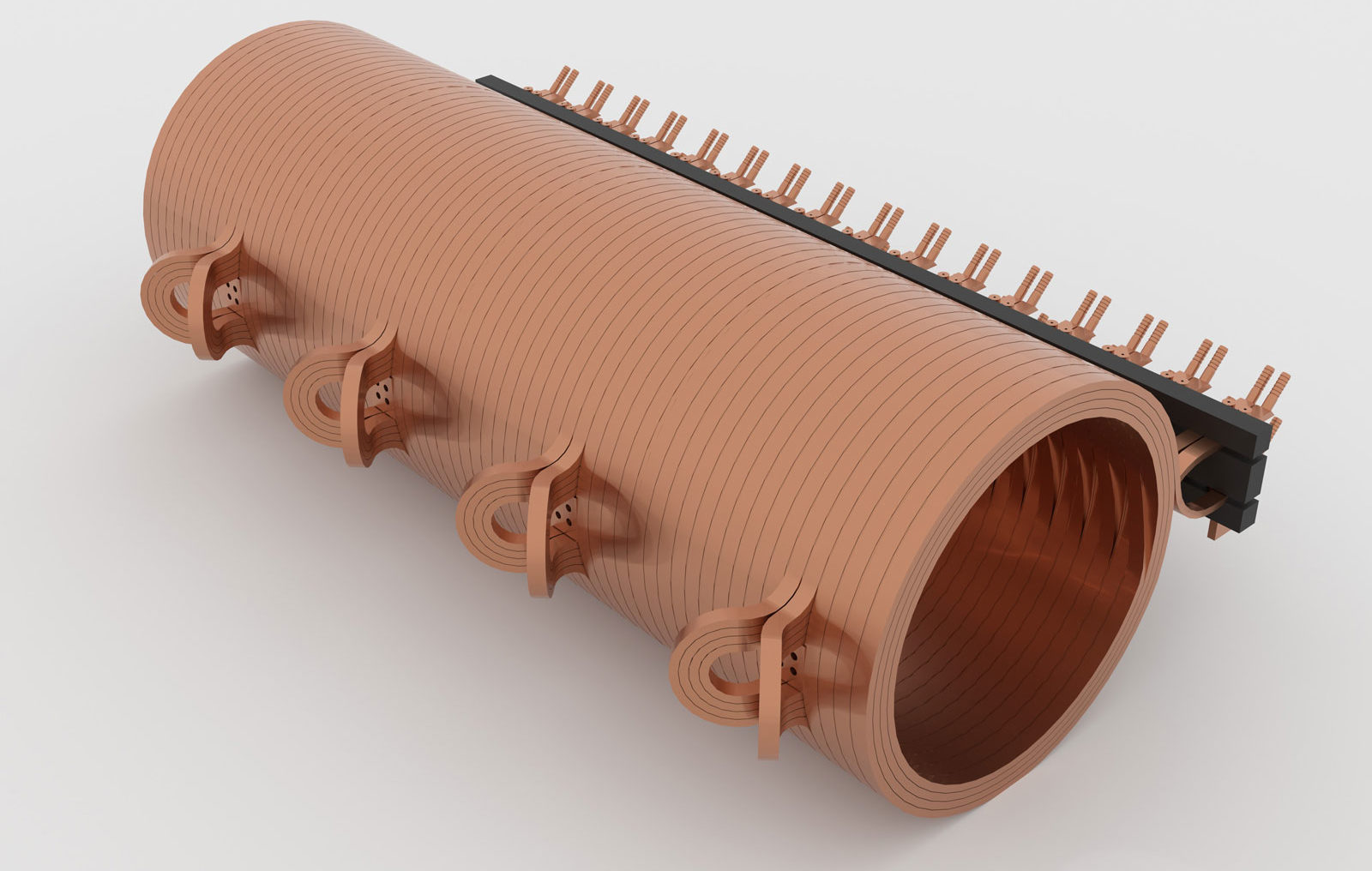

- Repair and remanufacture of complete crucible induction furnaces of all well-known brands

- Repair and remanufacture of inductors for channel-type furnaces of all well-known brands

- New manufacture of induction coils of all types

- New production of complete heating inductors for forming processes

- Repair and modification of induction heating equipment

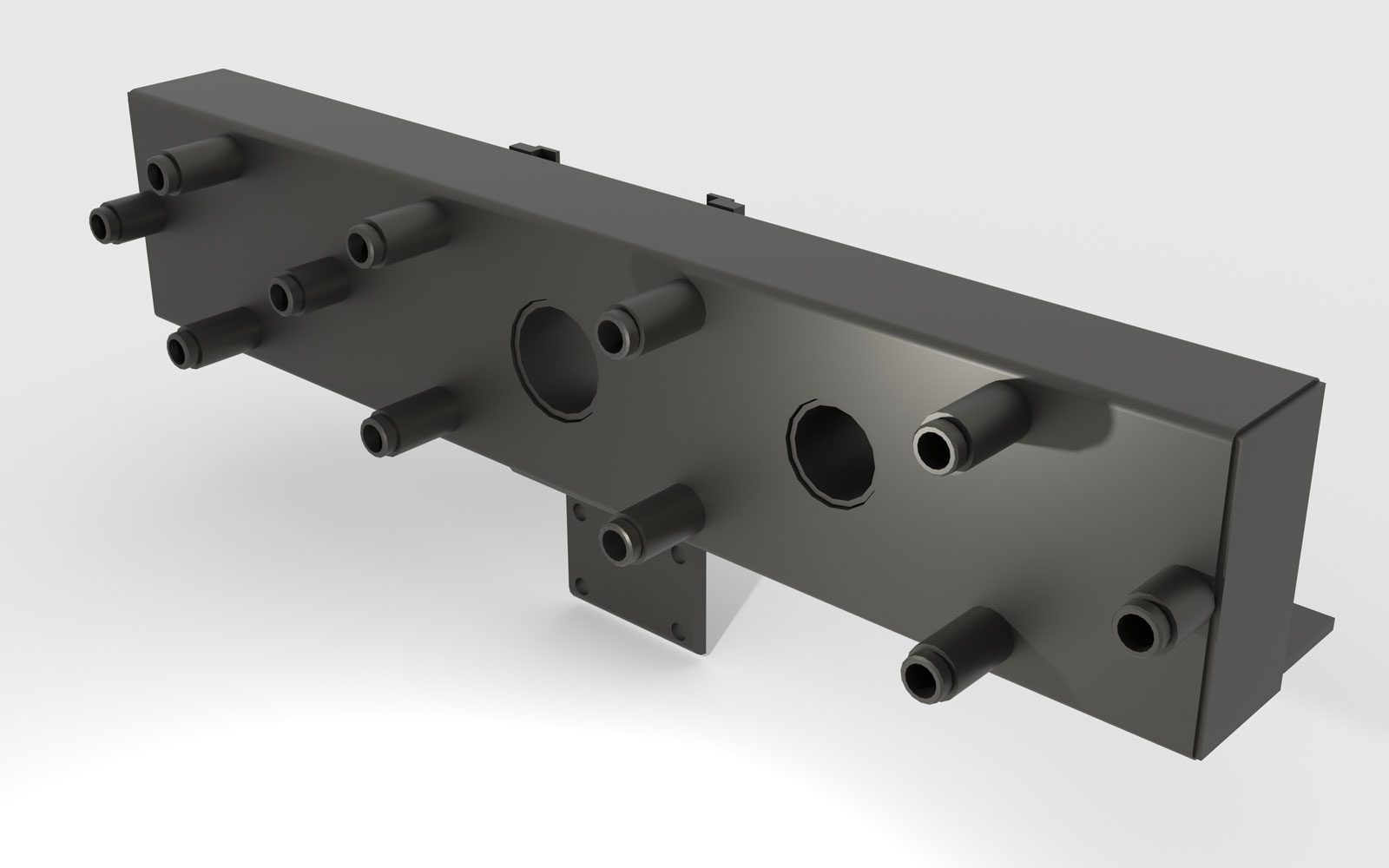

- Production of water-cooled protective cylinders for channel inductors

- Production of hollow troughs and tamping models made of copper or steel, as well as solid formed troughs

- Supply of spare parts such as power cables, magnet yokes, yoke insulation, cooling water hoses, insulating parts, conductor rails, as well as various concrete segments according to customer requirements

- New production of individual components such as chokes and transformers in air- and water-cooled design

- Preventive maintenance work

- Modernization and retrofitting of existing induction plants

- Performance optimization

- Installation and removal of furnace inserts and furnace systems at the factory

- Free storage and logistics of induction furnaces and coils

- On-site consulting, measured value recording and testing service

- On-site training courses together with our partners

Further information can also be found here: www.tct-induction.de

Training & Hilfestellung

Kontaktieren Sie uns für Ihren Schulungstermin

Die Arbeitswelt unterliegt durch wachsende Kundenansprüche und komplexere Aufgaben einem ständigen Veränderungsprozess. Dieser Wandel bringt unter anderem den Einsatz neuer Technologien und neuer Arbeitsweisen mit sich. Deshalb ist ein kontinuierlicher Lern- und Weiterbildungsprozess ein wichtiger Bestandteil des Arbeitsalltags geworden. Wir unterstützen Sie mit Wartungs- und Instandhaltungsschulungen sowie Beratung zu Prozessoptimierungen direkt bei Ihnen vor Ort an Ihren extrutec Anlagen oder bei Bedarf bei uns im Hause.

Upgrades

HARDWARE

New thermocouple assembly with exchangeable tips

The key advantages for using replaceable tips for thermocouples are significantly reduced material cost and quicker maintenance.

Maintenance becomes much simpler since not the entire thermocouple needs to be disassembled but only the tip is unscrewed, which saves significant time and money.

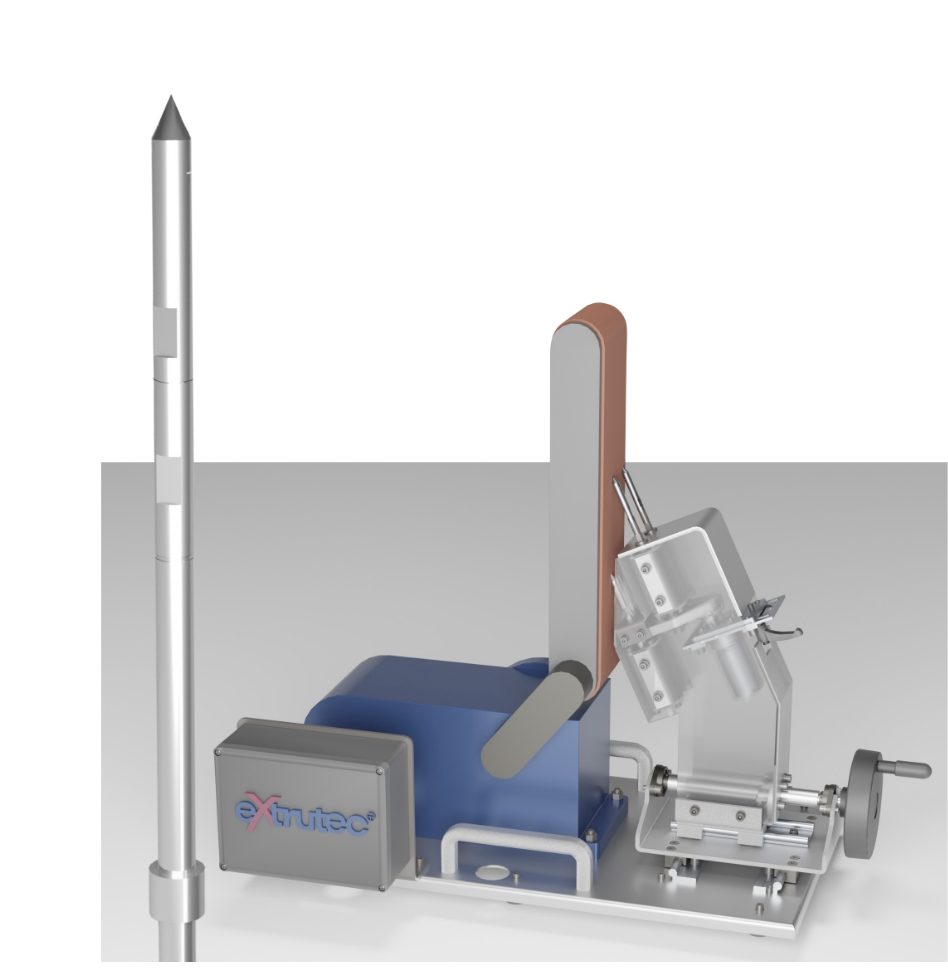

Thermocouple sharpening device

The thermocouple sharpening device provides a consistent grinding pattern and angle. Temperature deviations due to improperly sharpened thermocouples will be eliminated and material build up is severely minimized.

An important tool for the maintenance team, the sharpening device guarantees optimal sanding pattern and angle for better temperature measurement results

Complete control systems updates

The switchgear equipment, specifically for induction furnaces, is subject to high strain in continuous daily operation and its lifespan is therefore limited. Replacing the controls equipment not only makes sense to avoid downtime, but the improved energy efficiency results in an increase in process efficiency and the better utilization of the connected power.

Modern equipment concepts provide more precise process control when using the heating equipment and by replacing the mechanical switchgears with power contactors, the investment cost is reduced. Reduced electromagnetic interference, more even network utilization and the effective monitoring of process data are further positive side effects.

Our services are not limited to extrutec equipment only. We offer switchgear upgrades and maintenance service for third party equipment also.

SOFTWARE

Störmeldearchiv Störmeldetexte

Anlagenstörungen werden mit detailliertem Fehlertext beschrieben, was die Fehlersuche und Problemlösung deutlich vereinfacht.

Mit unserer Archivfunktion lassen sich alle Fehler analysieren und auswerten.

So können mögliche Schwachstellen der Anlage schnell erkannt und behoben werden.

Training & Support

The working world is subject to a constant process of change due to growing customer demands and more complex tasks..

Among other things, this change entails the use of new technologies and new ways of working. That is why a continuous learning and further training process has become an important part of everyday working life. We support you with service and maintenance training as well as advice on process optimisation directly at your site on your extrutec systems or, if required, at our premises. Contact Us to Schedule Your Training.

The world will be digital

With the digitization software „nEXT“ extrutec offers a digital platform with which everyone in the production chain (operators, maintenance staff, production supervisor, etc.) can collect and evaluate the data important to them individually.

The application can operate either online (access to data from anywhere) or offline (access to the data exclusively while on the company network).

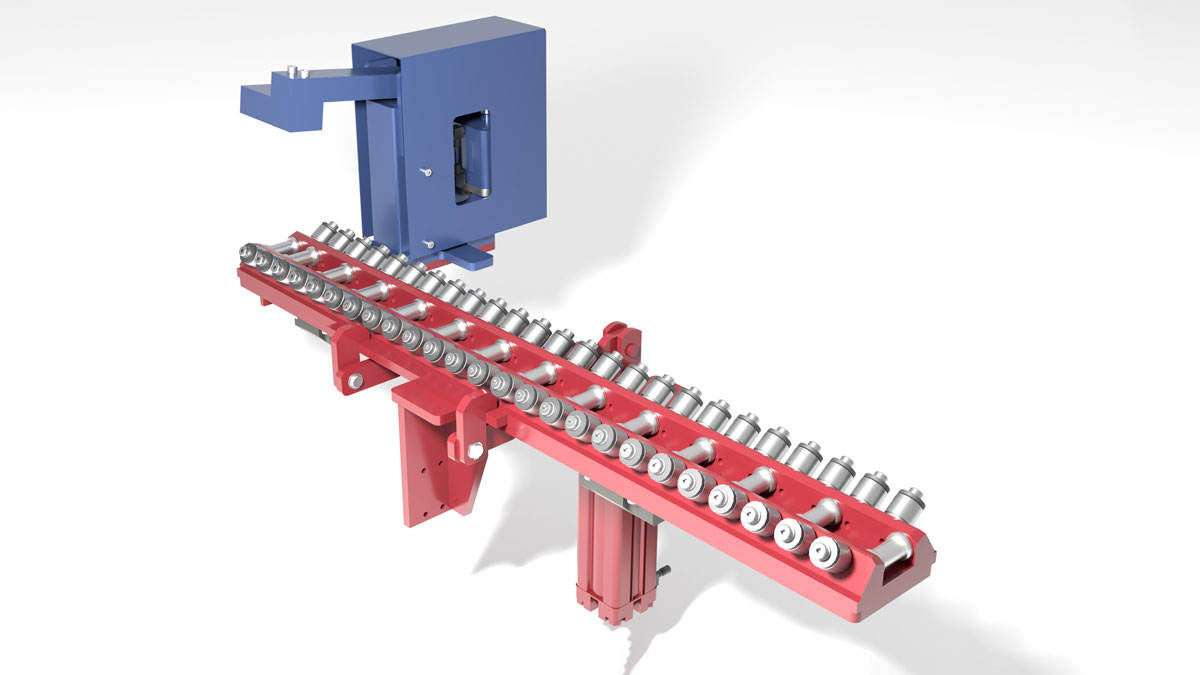

Consulting

How may we help you?

We offer advice in all matters regarding heating, cooling, and material handling, and help you find technical solutions for your ideas. Our experience and know-how in the field of heating technology for forming processes, heat treatment concepts in aluminium extrusion plants, and a wide range of special solutions allow us to point out available options and to advise you on choosing the best concept for your specific requirements.

We also help you in planning, support you with new acquisitions, analyse the potential of your existing plants or processes or show you existing improvement possibilities.

News

Fairs