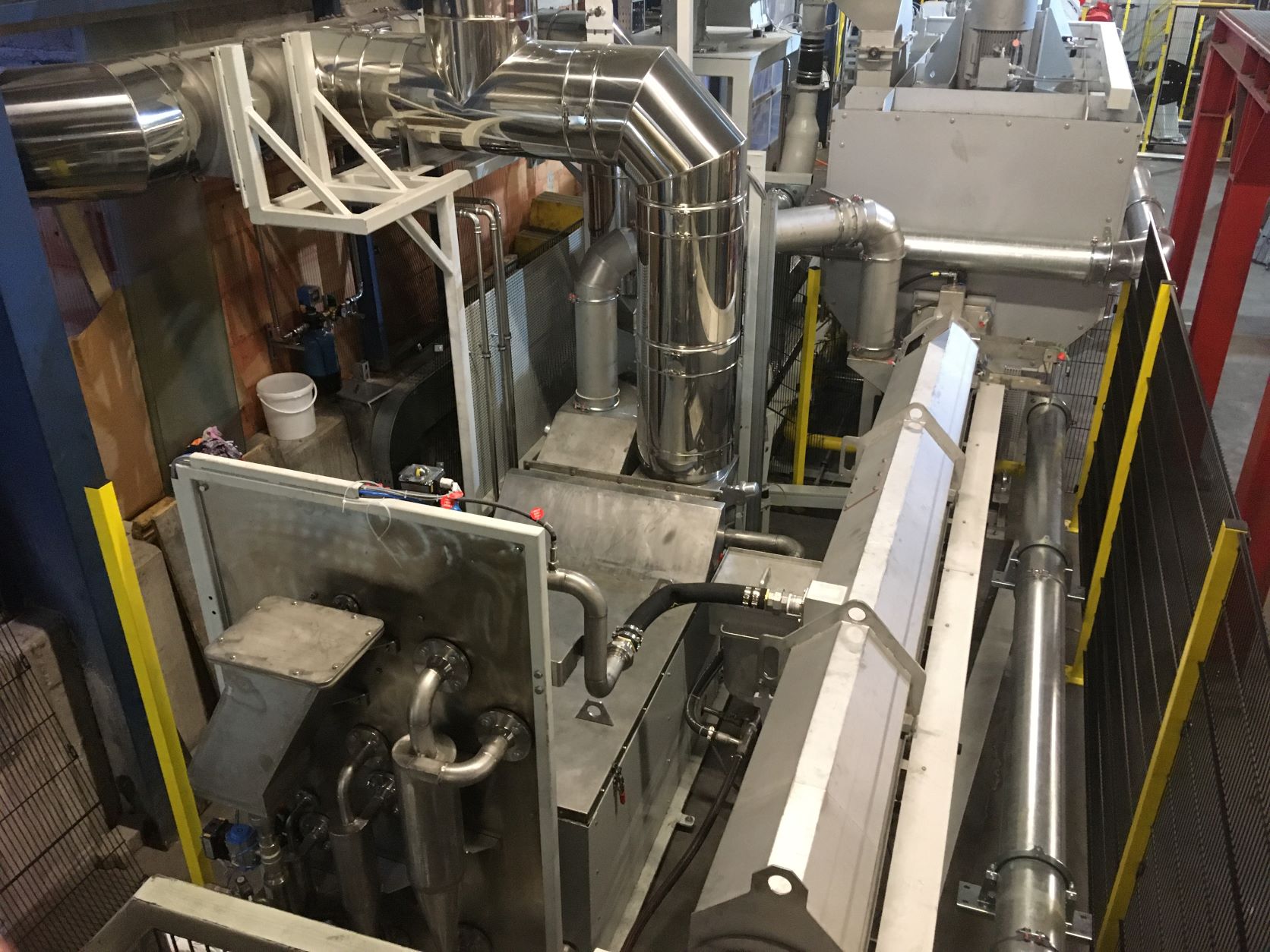

PRODUCT:

Log Preheating

We have been committed to a resource-preserving approach to fossil fuels, and therefore to the continuous effort to lower CO2 emissions as far as possible, from the very beginning. This guiding principle constantly drives us to develop new ideas and solutions. The most recent development is the Eco Shower Unit (ESU), for which a patent is pending.

Log Preheating

Special features:

- The Eco Shower Unit (ESU) uses the residual heat from the gas heater exhaust to heat up water to 90 °C (195 °F) in an air-water heat exchanger

- In a unit upstream of the gas heater, the aluminium billets are preheated to temperatures of up to 90 °C (195 °F) by laminar wetting of the entire surface with hot water

- The log preheating length is typically three times the log length

- A high-pressure log cleaning system can be integrated as an option

- Energy savings of approx. 15 – 17% are achieved, depending on the temperature profile

In addition, we have fundamentally redesigned the heat exchanger (previously a purchased part) and now manufacture it ourselves. The efficiency of the system was further significantly increased by the in-house development of the heat exchanger.

This is another innovation for the benefit of our customers and the protection of our environment.

Winner of the Metef Innovation Award 2022

During Metef 2022 in Bologna, extrutec's Eco Shower Unit (ESU) was awarded the Metef Innovation Award in the Technology and Processes category. The Innovation Award recognizes companies that have developed outstandingly innovative new technologies. The jury's particular focus was on the topic of sustainability and energy saving.

News