Milestones

History of extrutec

extrutec was founded by the managing partner, Uwe Günter, in 2005. Formly the company was based at the RIZ (Innovation and Technology Centre) in Radolfzell. At the beginning of 2021 we moved to our new company-owned building in Moos (near to Radolfzell) which is situated in the particularly attractive area of Lake Constance. The company, which operates on an international level, is mainly involved in the production of industrial plant systems for aluminium extrusion manufacturers.

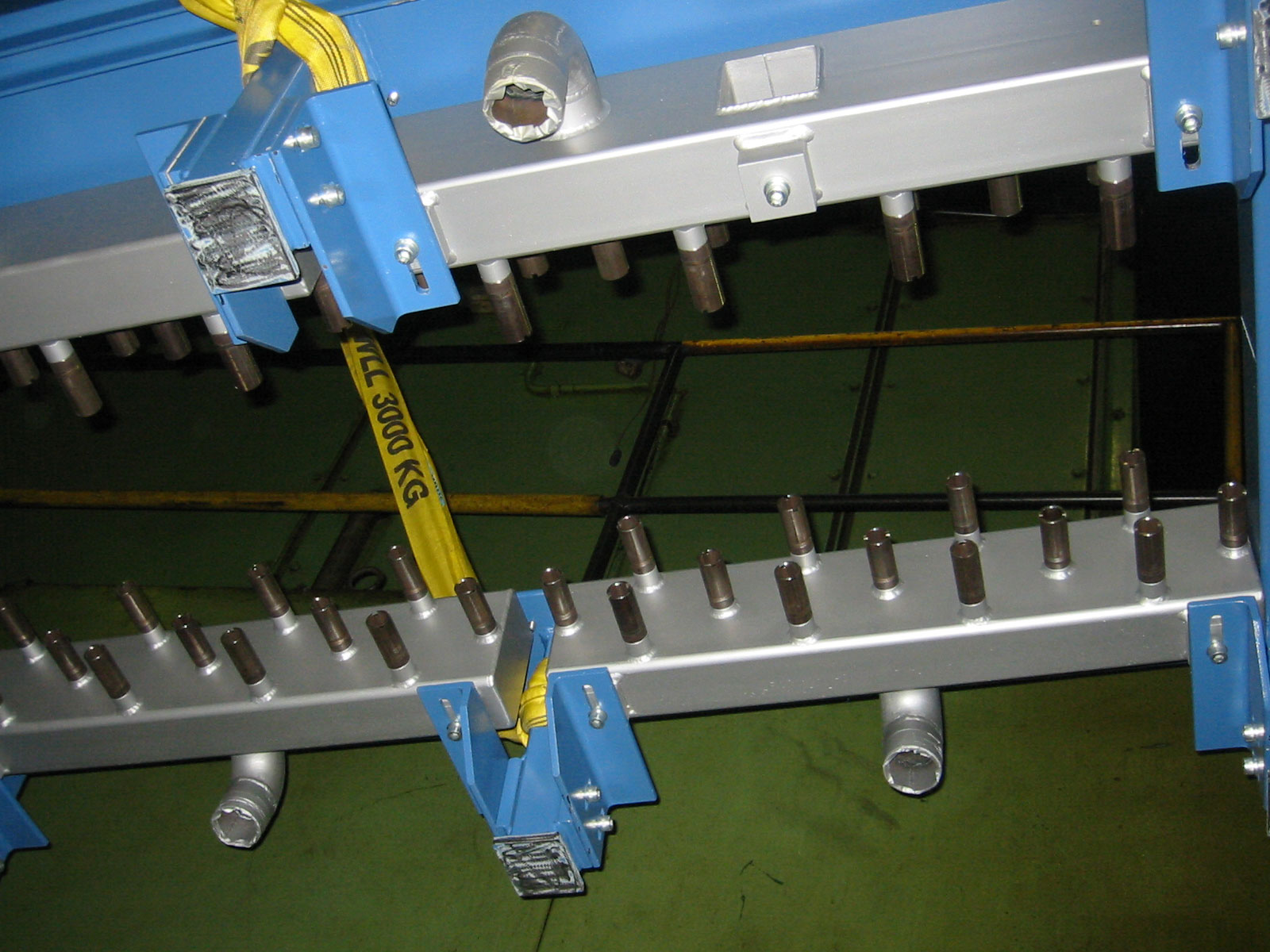

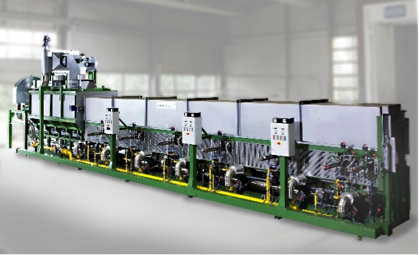

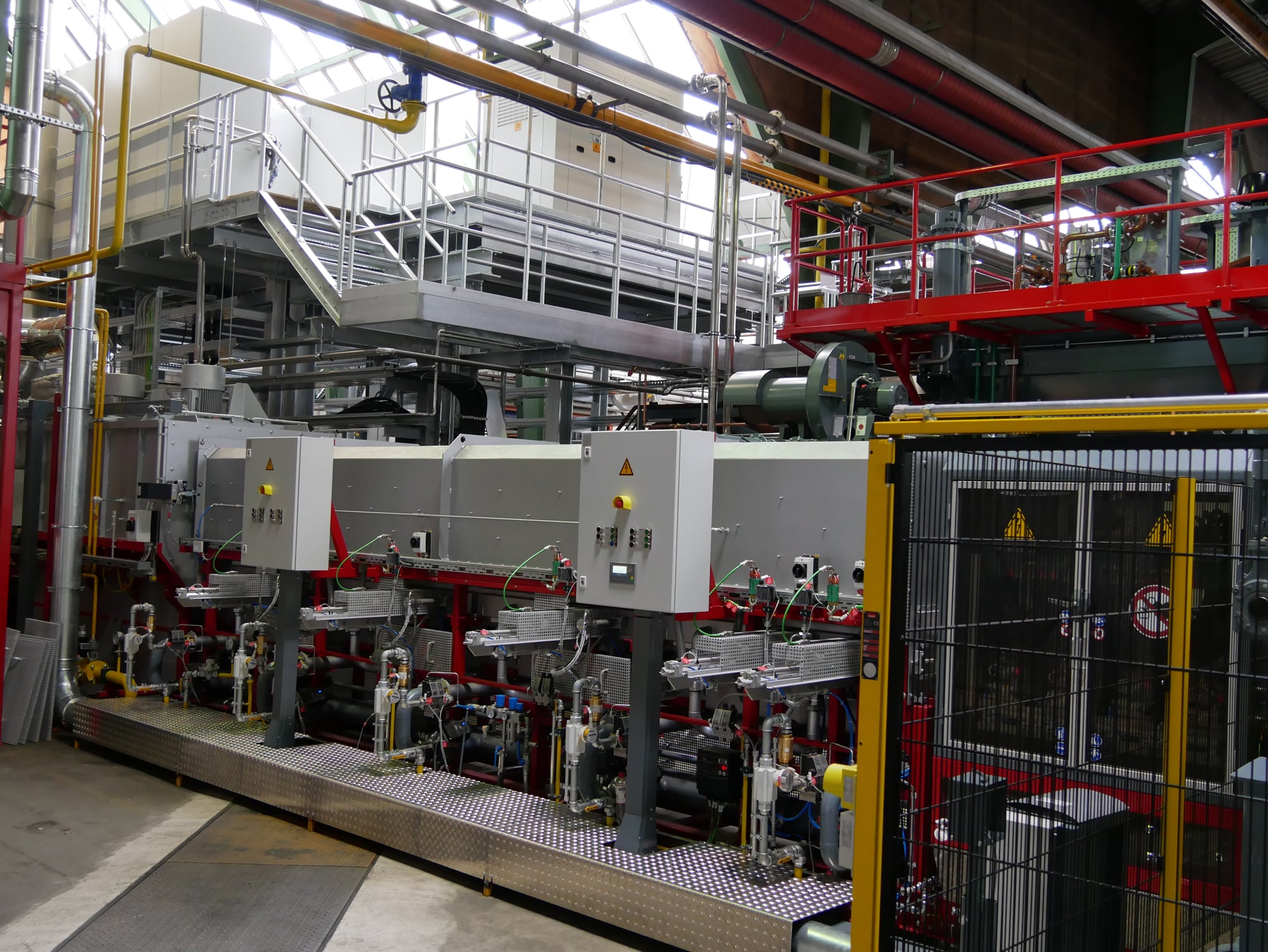

Development of a gas-fuelled log heating system for aluminium alloys with a new type of transport system, gas burners, and their optimised arrangement in the heater area and its introduction on the market. In addition, extensive activities in the area of spare parts and services as well as optimisation of various existing heater brands.

September 2006

Joachim Sokoll enters the company as technical manager (after working as head of design at Elhaus Industrieanlagen GmbH for more than a decade before). The sales volume exceeded the one million for the first time in 2006. Further personnel were recruited as well, in particular new colleagues with comprehensive industry knowledge.

The first two orders for the newly developed gas-fuelled heater facilities with hot shears were placed by Aluminium Menziken from Switzerland.

Further facilities and newly designed water quench system

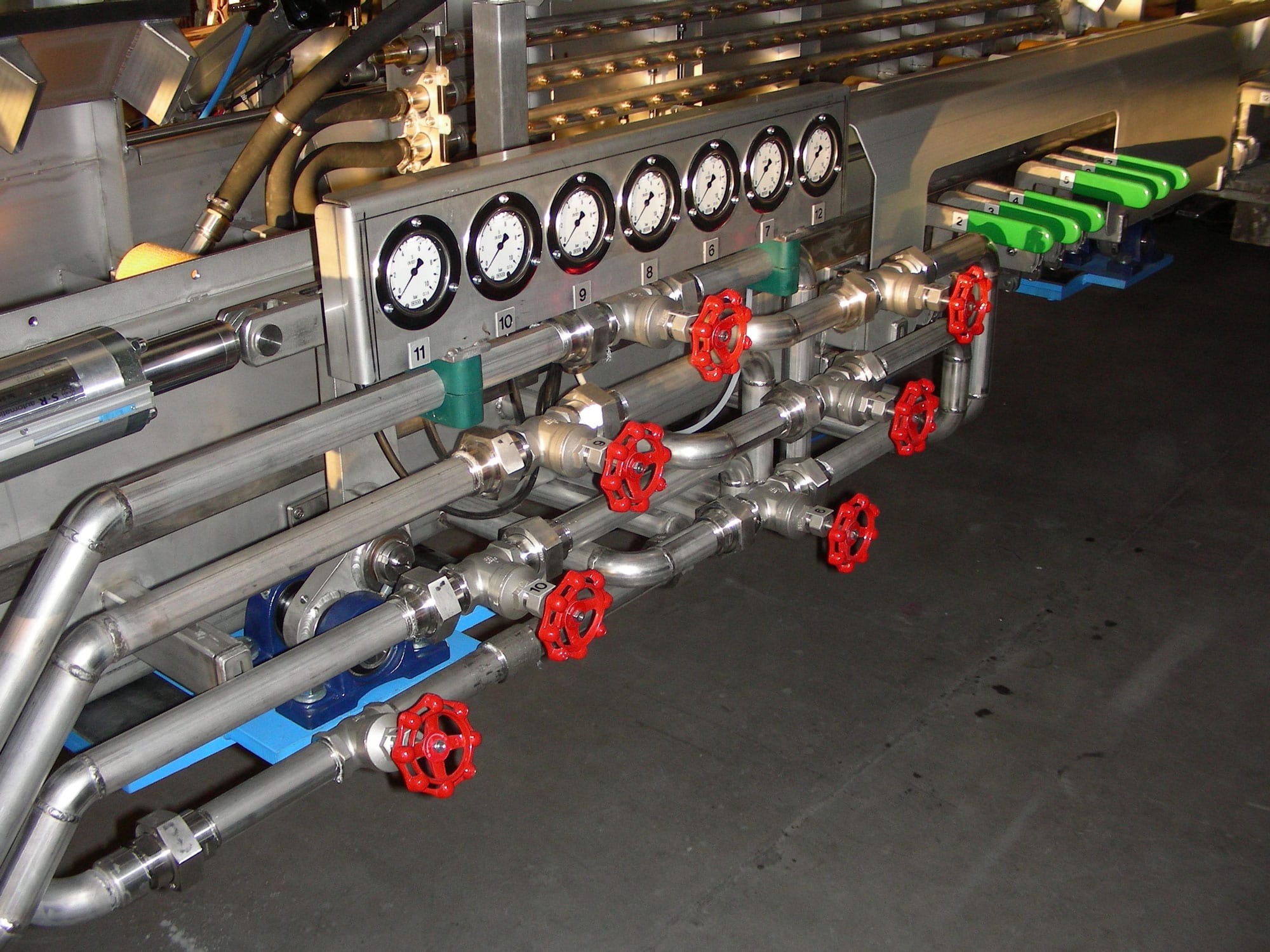

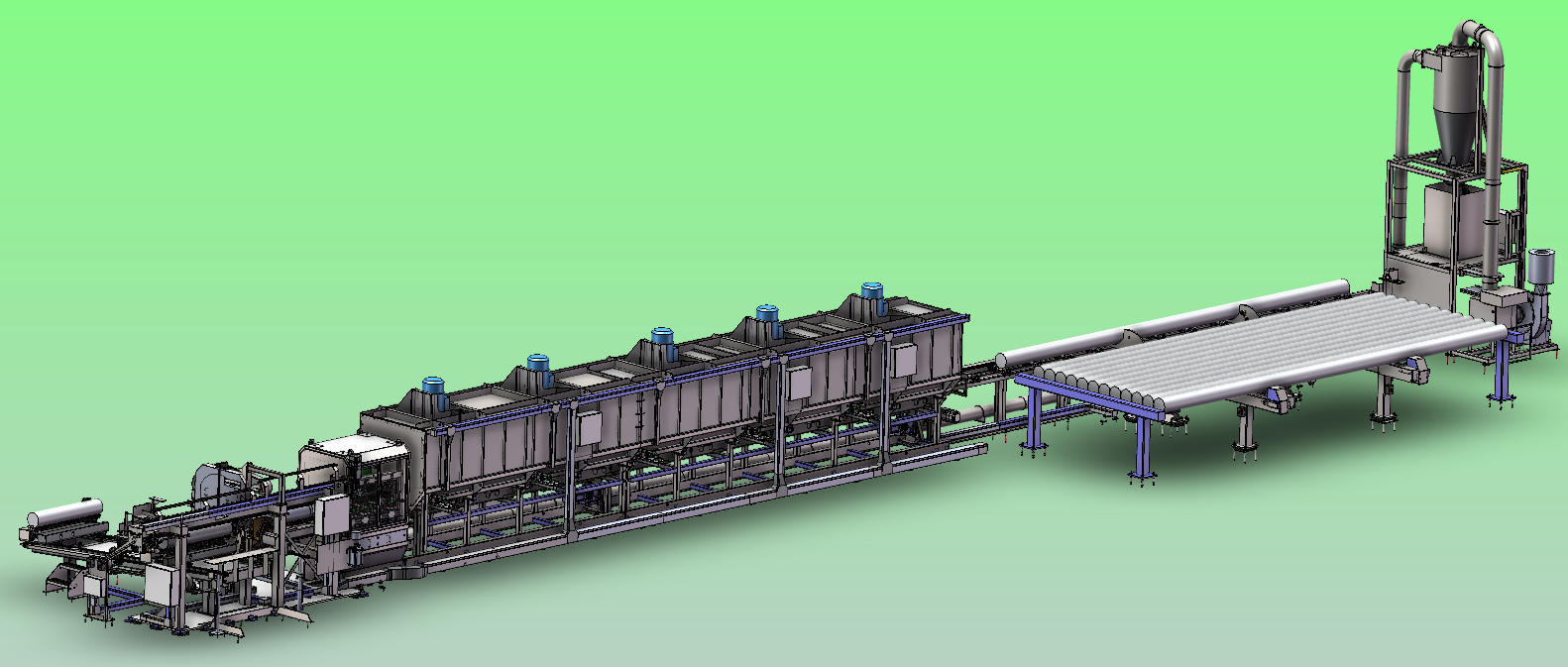

A total of 8 orders for new gas-fuelled heaters were placed in the course of the year (2 x Aluminium Menziken, Thöni from Austria, 2 x ASAS from Turkey, Purso and Nordic Aluminium from Finland, and FW Brökelmann from Germany). We also received our first order for a newly designed water quench system for intensive and extremely flexible cooling of AL extrusion profiles by Honsel (now Hammerer Industries Germany) in Soest.

Sales for 2007 are already more than twice as much as in the previous year.

The first order for a profile cooling system for the production of crash-capable Al-profiles was placed by FW Brökelmann from Germany. Further orders for gas-fuelled log heating systems were received from Hydro Aluminum Chrzanow in Poland and Erbslöh Aluminium in Velbert, Germany.

The début of a world novelty

Presentation of a world première at the aluminium trade fair in Essen. Together with IAS from Iserlohn, we developed a combination of a gas and induction heater arranged “in line” was developed and presented it to the experts.

In 2008 sales have doubled.

The first order for a log heating system was placed by a customer outside of Europe (Alupco from Saudi Arabia for its Jeddah plant).

The year of 2010 set the tracks for extrutec and its market position. Continuous new and further development of plants, as well as permanent dialogue with customers, led to the development of highly successful products, within in turn significantly generates orders. In this context, the number of employees almost doubled during this period.

Further Orders

Early in the year, Kety group from Poland placed their first order for an Al hot saw combined with an extrutec gas heater. The saw is equipped with horizontal stroke. All hot and cold log saws in the years to come will subsequently be designed as swivel versions, which offer considerable space advantages.

During the year:

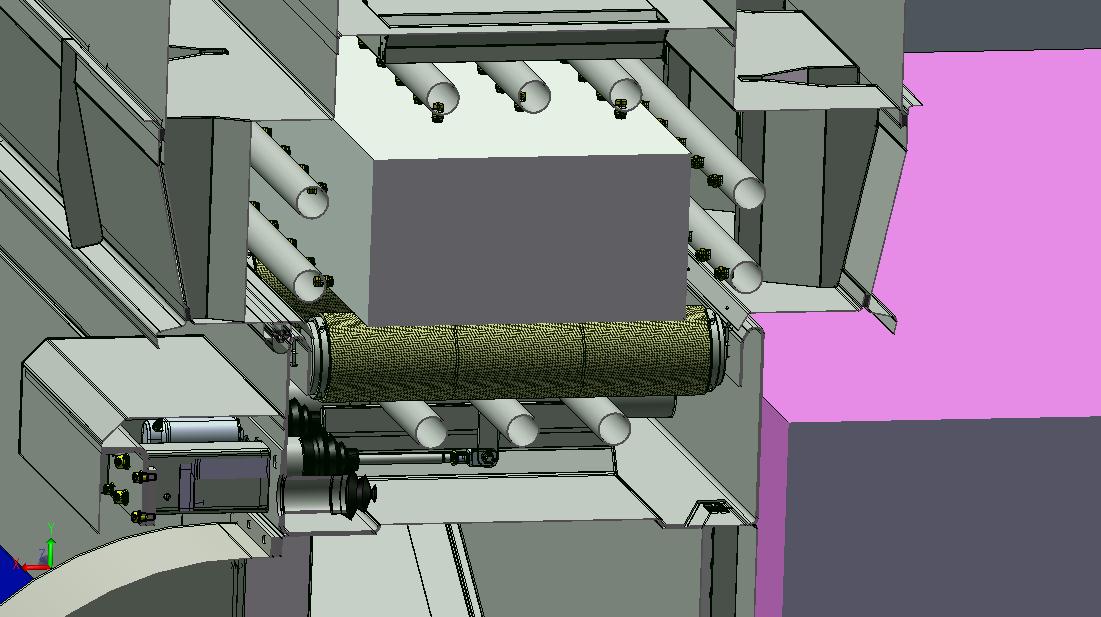

- Alcan (now Constellium) from Crailsheim orders the first In-line heater

- Thöni from Telfs, Austria, orders a total of 5 gas-fuelled ageing ovens

- Erbslöh Aluminium from Velbert orders the first high-pressure cleaning systems for rods and logs

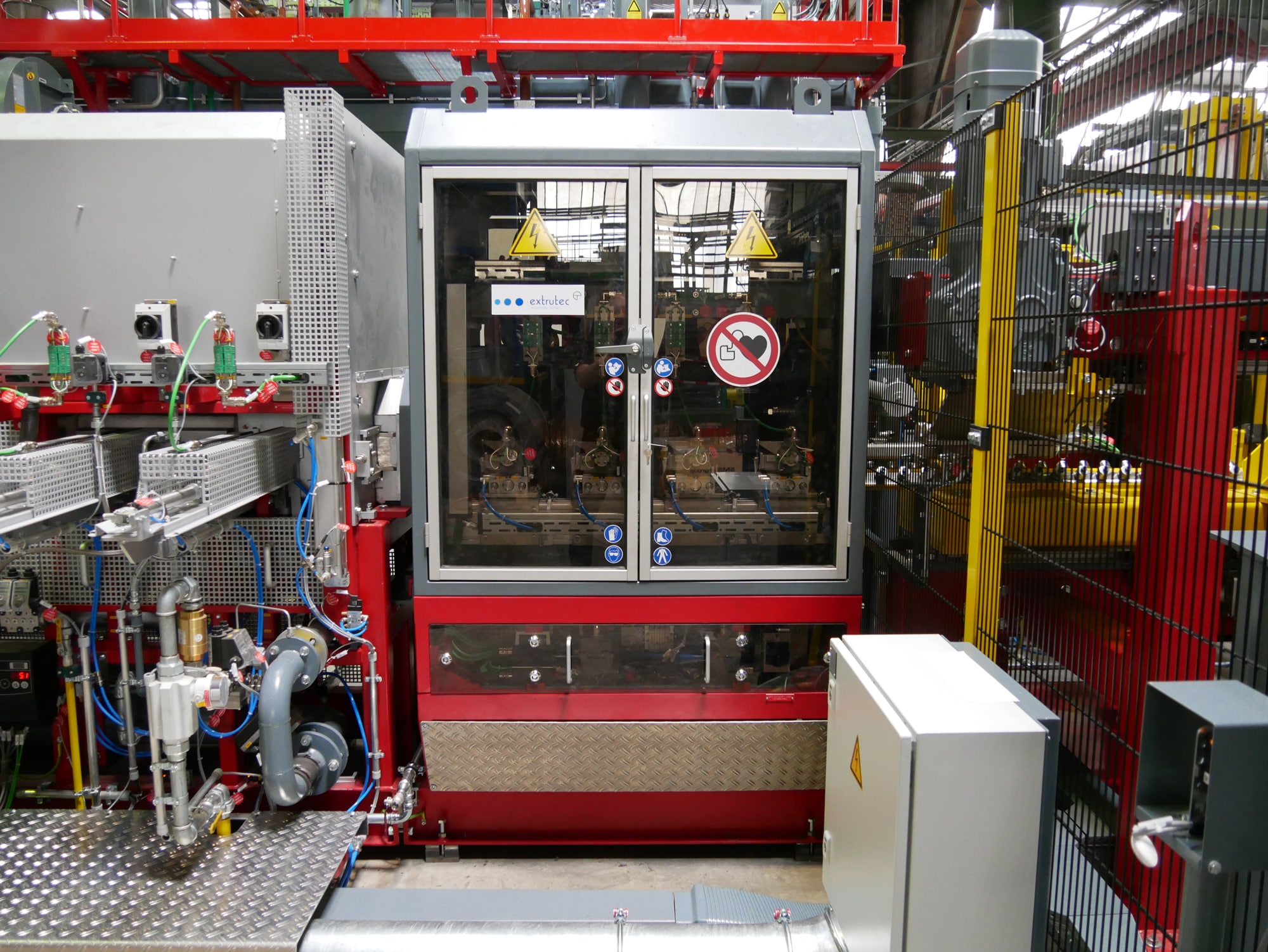

- apt Hiller (now apt Extrusions GmbH & Co. KG) orders the first die heater from extrutec

The company's internationalization continues in the business year of 2011 (Incoming orders from three continents outside of Europe).

Incoming orders total in excess of almost EUR 9 million for the first time in the company’s history in 2017. the number of employees increased in this business year as well.

Incoming orders during the full year will reach a record level of almost EUR 9 million and the number of employees also increased in this business year. For the first time, sales exceeded the 5 million mark in 2011.

Orders from China, Australia and the Netherlands

- First order from China is placed by Bejing Erbslöh China (Joint Venture with existing customer Erbslöh Aluminium from Velbert)

- Capral (largest and most important manufacturers of AL extrusion profiles in Australia) orders a gas heater system with hot shear from extrutec

- A order for gas heater system with triple gas taper, hot shears and vertical magazine for rods was placed from South America (Hydro Aluminium Acro near Sao Paulo, Brasilia)

- Nedal Aluminium from the Netherlands placed an order for another in-line heater with hot saw. With a rod and log diameter of 14" (357 mm), this is the largest active in-line heater system to date.

Further orders for profile cooling units were placed by the HAI group (main plant in Ranshofen in Austria). Continuous further development of this product group has given extrutec a special position in the market.

Weseralu from Minden, Germany, placed an order for another in-line heater with hot saw, a convective rod preheating magazine and a vertical magazine for 260 rods (diameter 10").

Orders from Switzerland an Italy

- Aluminium Laufen AG from Switzerland placed a large order with extrutec for the supply of a 10" cold log saw with rod and log handling, ageing ovens, and an overhead die heater with nitrogen operation

- Two orders were received from the country of the largest market players. In the following year, a gas heater, and an overhead die heater were delivered to southern Italy for BBC

extrutec received several orders from outside of Europe in the business year of 2014 as well. In addition to an 11" log heating system with hot saw from Hydro Aluminium in China, a fully automatic overhead die heater system from Yasuda Metals in Japan stands out in particular. Thöni from Telfs, Austria, placed another order with extrutec for a state-of-the-art profile cooling system.

Replacement for old Technologies & Further Orders

ASAS from Turkey charged extrutec with the delivery of a 14" hot saw. It is particularly worth mentioning that extrutec is going to replace its own log hot shears from 2008 with this system. At the same time, however, this development clearly reflects that the technology of cutting heated aluminium rods with hot shears has been replaced for good.

Among other things, extrutec received further orders for an in-line heater with hot saw (Thöni from Austria), a full plant (log heating, ageing ovens, and die heaters) from Saudi Arabia (Ajial from Riyadh), and a first hot saw from Gulfex from Dubai.

At the end of the year, Mäkelä Aluminium from Finland places another order, this one covering a cold log saw with various rod and log handling systems. The order also includes a highly sophisticated logistics system for log transport in the area of inductive log heating systems.

Business year 2016 with: Profile cooling system for Neuman from Austria, hot saws ) to replace hot shears (e.g. Thöni), first order from Greece (gas heater with hot saws and an overhead die heater for Cosmos Aluminium) and a 15" log heating system from another renowned customer from North-Italy.

Investment activity, in particular in the region of Central Europe, is increasing noticeably. extrutec registers incoming orders for, among other things, two in-line heaters with hot saws (Sapa Uphusen and apt Extrusions GmbH & Co. KG), several hot saws (e.g. Gulfex from Dubai) to replace hot shears, and four additional gas-fuelled log heating systems.

Incoming orders total in excess of EUR 10 million for the first time in the company’s history in 2017.

In this business year the demand for systems from extrutec are increasing again. In all product sectors (7 log heating system, a hot saw for the exchange of a hot shear, 6 ageing ovens, 3 profile cooling systems and two die heaters) orders are mainly placed by European customers. In addition to many existing customers, exlabesa from Spain orders various systems for the first time, which are installed at locations in England, Morocco, Germany, Spain and Poland.

Due to the increase in volume the number of employees increased to 25.

Patented Energy saving

On the occasion of the aluminum fair in October 2018, extrutec group from Poland placed their first order for an Al hot saw combined with an extrutec gas heater. The saw is equipped with horizontal stroke. All hot and cold log saws in the years to come will subsequently be designed as swivel versions, which offer considerable space advantages.

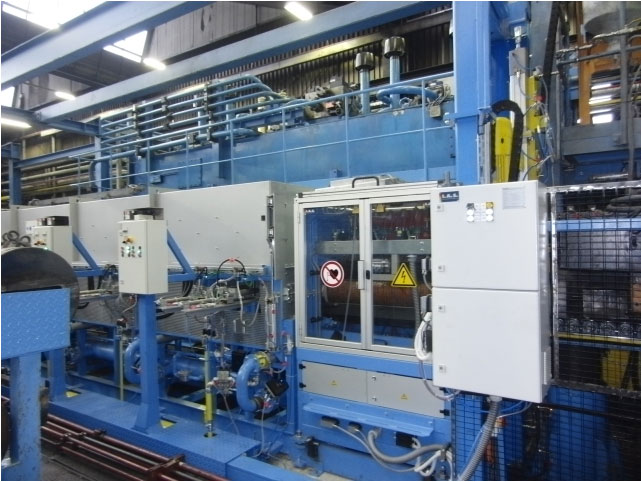

This business year will be the biggest change in the company's history. In the second half of 2019, Stefan Beer, the longstanding managing director and co-owner of IAS changing to extrutec. This means that we have been able to add a new range of all kinds of products to our induction heater system portfolio.

In this business year, several inline heater systems of the latest generation developed by extrutec have been sold.

In 2019, further records were also achieved in sales (ca. EUR 15 million) and new orders.

The year 2020 started with a joyful event for extrutec, the groundbreaking ceremony for the new office and administration building in the community of Moos on Lake Constance near Radolfzell. The new building, which was planned well in advance, will allow extrutec GmbH to continue its expansion and at the same time ensure the increased needs of an innovative working environment. As with extrutec GmbH's own products, particular attention was paid to the energy efficiency of the building.

At the end of the 1st quarter of 2020, however, the Corona pandemic became a major challenge for all people on this earth. This also marked the beginning of a very uncertain phase for extrutec, its customers and partners. But also this difficult situation could be mastered with united forces without noticeable restrictions. Due to extrutec's forward-looking mentality, there was no question of standing still, so the capacities freed up were used for the further development of products and the complete reorganization of extrutec's external image. In the course of the year, not only the new corporate design of extrutec GmbH could be presented, but also numerous orders could be booked in all product areas (e.g. Cansan and Asen Metal from Turkey) despite the continuing pandemic.

As of 01.01.2021, the newly founded TCT Induktionstechnik GmbH based in Iserlohn also belonged to the extrutec group. In addition to its original activities in the service and repair of technical foundry equipment, the subsidiary, which was created through an asset deal, is now involved in the manufacture of inductors, recooling systems, etc. for billet heating. Also the maintenance and repair of coils of any type belongs from the beginning to the tasks of TCT Induktionstechnik GmbH.

During the year, the renowned Aluminium Journal ran the headline "extrutec has successfully used the Corona crisis". In the published article it was not only possible to report about the new external appearance, but a multitude of new inventions of extrutec GmbH could be presented to the public. Thus two patents and two further trade marks were registered. The Alpha Flex Technology and the electrically resistance heated high convection inline oven (EHKO) are the latest patents of extrutec GmbH. In addition, the Power Focus TechnologyTM a further development of the extrutec induction furnace and the Eco Heating Process (EHPTM) a highly efficient heating process consisting of various extrutec technologies, have been established as trademarks.

Since September 2021, extrutec North America is also part of the extrutec group as a sales organization, but an independent and registered company. The office is located in the premises of the company WEFA. extrutec cooperates on the American market with the renowned manufacturer of extrusion tools from Singen With this foundation of the company, the activities to penetrate the highly interesting North American market will then be considerably strengthened again. The extrutec group's corporate development continued to be extremely successful in 2021. Order intake and sales were once again increased.

Unfortunately, 2021 and 2022 were characterized by interrupted supply chains, drastically increased delivery times and noticeable price increases in the area of procurement. Fortunately, in 2022 we were again able to acquire numerous new customers in Turkey and, towards the end of 2022, a new customer in South Korea (Almac). Order intake in 2022 once again exceeded all expectations. Numerous and very interesting orders were booked in all product groups. The renewed substantial growth led and leads consequently to expansions at the two locations in Germany. In the course of the year 2022 it was then also decided to give up the location in Iserlohn and to move with TCT Induktionstechnik GmbH into a completely new administration and production building, designed according to the company's own ideas and built by a local property developer. The move to the new domicile in Menden will take place in the third quarter of 2023.

News

Fairs