Service

Always Well Advised

With our experienced team, we ensure that customer wishes are realised quickly, reliably and competently. We offer a wide range of service and maintenance work around extrutec systems. Depending on the customer’s requirements, our services are offered as on-site service at the customer’s premises or as workshop service in our modern equipped facilities.

Repair / Maintenance

Induction coil repair, maintenance and replacement

When it comes to induction coils, we can look back at a wealth of experience and knowledge. This allows us to offer repairs, maintenance, and complete replacements for coils of all makes. Our specialists in Menden cover all aspects from engineering to fabrication in-house.

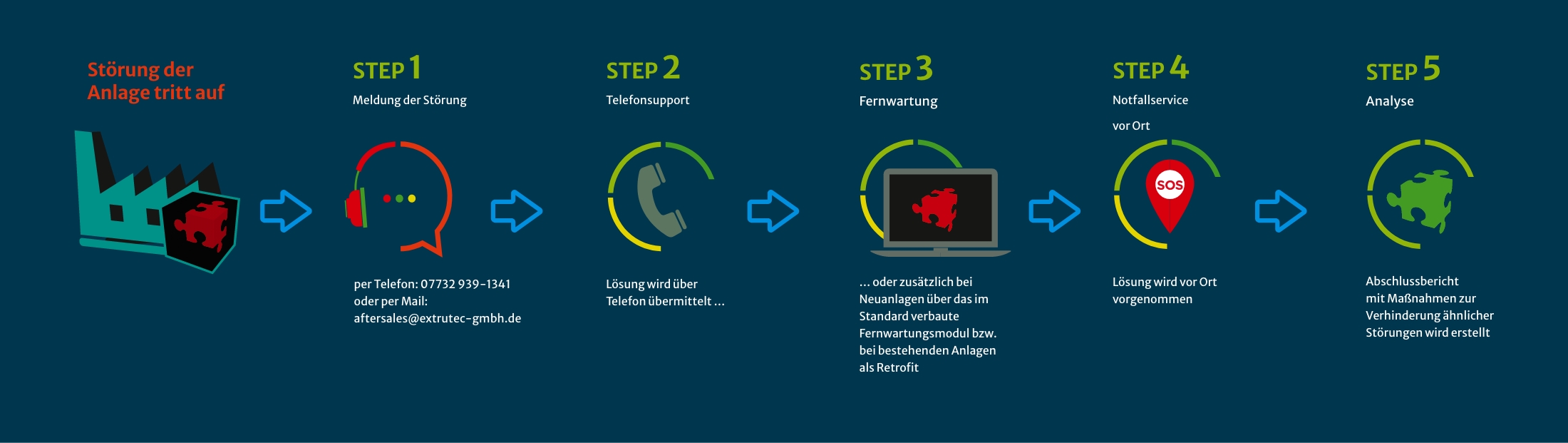

Troubleshooting

Remote support

All new extrutec equipment is equipped with a remote support modem as a standard. This enables extrutec to efficiently access the equipment remotely, when assistance is requested by the customer.

We use a system by Secomea, which provides state-of-the-art cyber security. The remote module is integrated into the control cabinet and provides explicit access control to the customer via a key switch in the control cabinet, as well as explicit authorization by the customer’s IT-department. The connection is end-to-end encrypted.

For any equipment historically supplied without a remote access module we strongly recommend a retrofit. Having this access enables our technicians to troubleshoot remotely, solve any issues quickly and efficiently, often avoiding onsite travel.

Our aim is to keep downtimes to a minimum and maximize the availability of your systems.

As soon as a fault is detected, it can be reported immediately by telephone or e-mail. Our team is available to process your inquiries and provide the necessary support. For more complex problems that cannot be solved immediately over the phone, we use our remote maintenance module. However, if a fault cannot be resolved remotely, our emergency service is ready to intervene quickly and effectively on site. Our technicians are trained to carry out all necessary repairs directly on site.

Onsite

Combustion maintenance

An annual adjustment of the combustion system of your gas furnace will noticeably reduce your gas consumption. This furthermore lowers the CO2 levels significantly.

Years of experience and regular training enables our service technicians to also service the combustion systems of third-party providers.

EMC assessment

In January 2023 the TREMF-NF regulations were introduced setting exposure limits to magnetic fields. This forces employers to ensure comprehensive considerations are given to occupational safety when operating induction furnaces and other electrically heated furnaces and ovens. Extrutec can support you by making an EMC assessment, determining the exposure area and defining the appropriate measures.

Inspections and maintenance

Step 1 is to perform an inspection of the equipment based on an individual checklist. This means all relevant wear parts are checked and a list of all required spare parts is compiled and the spare parts order is processed

Step 2 covers the installation of the replacement parts by our service staff as soon as the parts have arrived. Following the installation our service technicians will assist when production resumes.

Measured Value Recording/EMC

Specified limits of electric and magnetic field strength must be complied with for the protection of people in the vicinity of high-frequency or low-frequency plants. For low-frequency and high-frequency facilities with significant power, immission measurement is, therefore, mandatory and part of the employers’ care obligations, e.g. within the framework of occupational health and safety.

Our measurements based on many years of experience in the field of measuring electromagnetic fields (EMF) and our extensive modern equipment comply with the following regulations:

- E DIN VDE 0848-3-1: Safety in electrical, magnetic and electromagnetic fields

- Provisions of the employer’s liability insurance association on safety and health at work, DGUV 15 (formerly BGV B11)

- European specification: Occupational Health and Safety Directive 2013/35/EU on electromagnetic fields

Optimization

Optimization of consumption

The efficiency of equipment slowly deteriorates over time due to the high utilization over the lifespan of the equipment. This loss of efficiency can be minimized by regular hardware and software updates. After an initial onsite investigation, we will develop the appropriate measures for optimizing your equipment efficiency.

Smart temperature measuring intervals

Rather than using fixed measuring intervals for the thermocouples, these cycles are controlled smartly and temperature dependent, with the help of individual temperature profiles stored in the PLC. This reduces maintenance of the thermocouples and at the same time saves energy by minimizing infiltration of excess cold air.

Consulting

How may we help you?

We offer advice in all matters regarding heating, cooling, and material handling, and help you find technical solutions for your ideas. Our experience and know-how in the field of heating technology for forming processes, heat treatment concepts in aluminium extrusion plants, and a wide range of special solutions allow us to point out available options and to advise you on choosing the best concept for your specific requirements.

We also help you in planning, support you with new acquisitions, analyse the potential of your existing plants or processes or show you existing improvement possibilities.

News

Fairs